Quality coffee isn’t about the caffeine content—it’s about the process, the flavour, and the ritual. Understanding what happens at the farm and beyond shapes the story of the coffee in your cup—whether you choose a caffeine hit or not. But how is coffee decaffeinated? What are the different decaf processes?

We take a closer look at all things decaf.

WHAT IS DECAF COFFEE?

Stripped back to basics, a decaf coffee means the coffee is essentially caffeine free. It’s important to note there still is some caffeine in decaf coffee, with decaffeination processes typically removing 97-99% of the stimulant.

WHAT IS CAFFEINE?

Caffeine is a natural compound that occurs in different plants and foods such as coffee beans, tea leaves, and cacao pods. Caffeine can also be manufactured in a laboratory and added to everyday food and drink, or used in certain medications. Commonly associated as a stimulant for the brain and central nervous system, there’s a good reason why that first cup of morning coffee is essential for many.

A regular cup of coffee in an 8oz cup can have as much as 70 - 200 mg of caffeine whereas a typical cup of decaf coffee averages between 2 - 15 mg of caffeine in the same size cup.

THE HISTORY OF DECAF

Ludwig Roselius is credited with launching the first commercially successful decaffeination process (although it is believed that there were successful experiments prior to the early 1900s). The German coffee merchant observed that when coffee carried on a cargo ship had been soaked by seawater, the caffeine content in the coffee had significantly dropped—but the flavour remained.

Taking this concept one step further, Ludwig experimented and discovered that by steaming the beans with different acids before using a solvent to remove the caffeine, decaffeinated coffee could be created. While no longer used today, the process paved the way for decaf production over the next 100 years.

THREE COMMON DECAFFEINATION PROCESSING METHODS

-

Co2 Processing

This process involves submerging the unroasted green coffee in warm pressurised water to open up the coffee bean, expanding the coffee and making it more porous. Carbon molecules are then added to the water which attract and bind with the caffeine molecules.

This process doesn’t draw out any of the carbohydrates and proteins which are what give the coffee its flavour. The water and carbon dioxide are then removed, and the coffee dried. The by-products of this process are recycled, with the water filtered and reused, while the filtered content is extracted and turned into cow feed.

Our partners, CR3, in Germany, oversee this entire process, ensuring the highest standards throughout to result in an exceptional decaf coffee.

-

Sugarcane

The Sugarcane process is sometimes referred to as ‘Natural Decaf’. Made from the fermentation of sugarcane, a readily available species from the grass family that creates Ethanol Acetate (EA), EA is a natural organic compound that is commonly found in fruits such as pineapples, oranges, and bananas.

The process expands the pores of the coffee beans by lightly steaming them for 30-40 minutes in a silo. The coffee then is rinsed in a combination of EA from non-GMO Colombian sugarcane and mountain water for 10 hours. After this, more water and steam are introduced to ensure the caffeine and unwanted residues are thoroughly removed. Finally, the decaffeinated coffee beans are dried to a desired moisture content of around 12%.

The beauty of the Sugarcane process is that it helps preserve most of the original flavours of the coffee, while adding fruity notes and further complexity to the cup. The carbon footprint of this coffee is significantly less than other processes, too, processed locally in Colombia, then shipped over to UK directly.

-

Swiss Water Method

The Swiss Water Decaf (SWD) is an innovative process centred around Green Coffee Extract (GCE), a solution that contains all the natural occurring water-soluble solids found in green coffee such as amino acids, carbohydrates, and minerals. The plant at Swiss Water use this GCE solution for every coffee they decaffeinate. It's like a living liquid, ever-evolving, and is continuously monitored and refreshed as a result.

The SWD process can be broken down as follows:

- Providing the plant with green coffee that requires decaffeination.

- This coffee is cleaned and then rehydrated in warm water to prepare for a moisture level that is ideal for caffeine removal.

- GCE is then added to the water and circulated for 8-10 hours until there is no more than 0.1% of caffeine remaining. Adding the GCE creates an imbalance and causes the caffeine to leave the coffee and combine with the GCE.

- The coffee is then sent to a dryer to be bagged and shipped out.

- The now saturated GCE solution containing caffeine is then sent through a carbon filtration system. This burns away the caffeine molecules, allowing the GCE to be reused for the next batch.

The entire process is chemical-free and organically certified, with the headquarters operating out of Canada.

OUR APPROACH TO DECAF

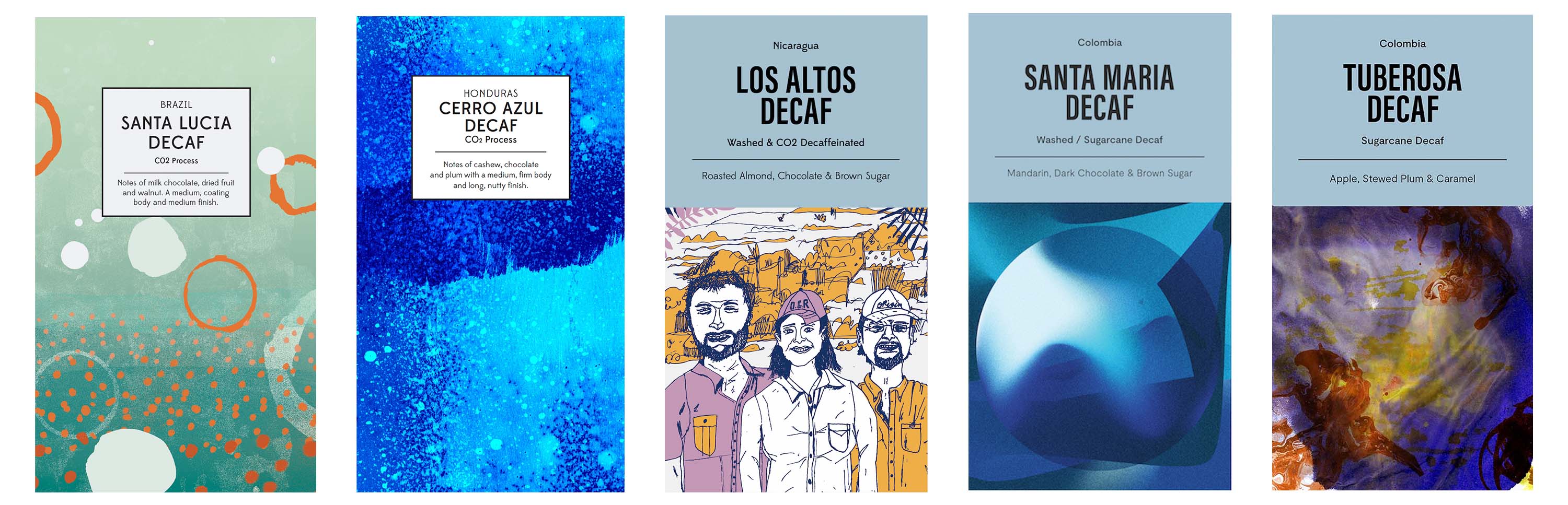

For us, decaf coffee starts with sourcing coffee that will benefit from how the process influences the final cup. This is why we seek out coffee with high acidity but approachable flavours like caramel, butterscotch, and just a slight bit of fruit. The decaf process calms acidity, resulting in a very rounded cup. Starting high means we have enough acidity to support complex flavours.

We then ensure we process coffee to decaf as often as possible.

Decaffeination processes result in a shorter freshness period for coffee, softening flavours found in the bean. We tirelessly work with coffee producers to get fresh coffee from the source as often as possible. This is why you’ll see us change our decaf every couple of months. This need for fresh decaf coffee means we get to work with many producers, increasing the amount of coffee we buy from them, enriching the relationships we have and creating space for quality coffee to be bought at the price it deserves.