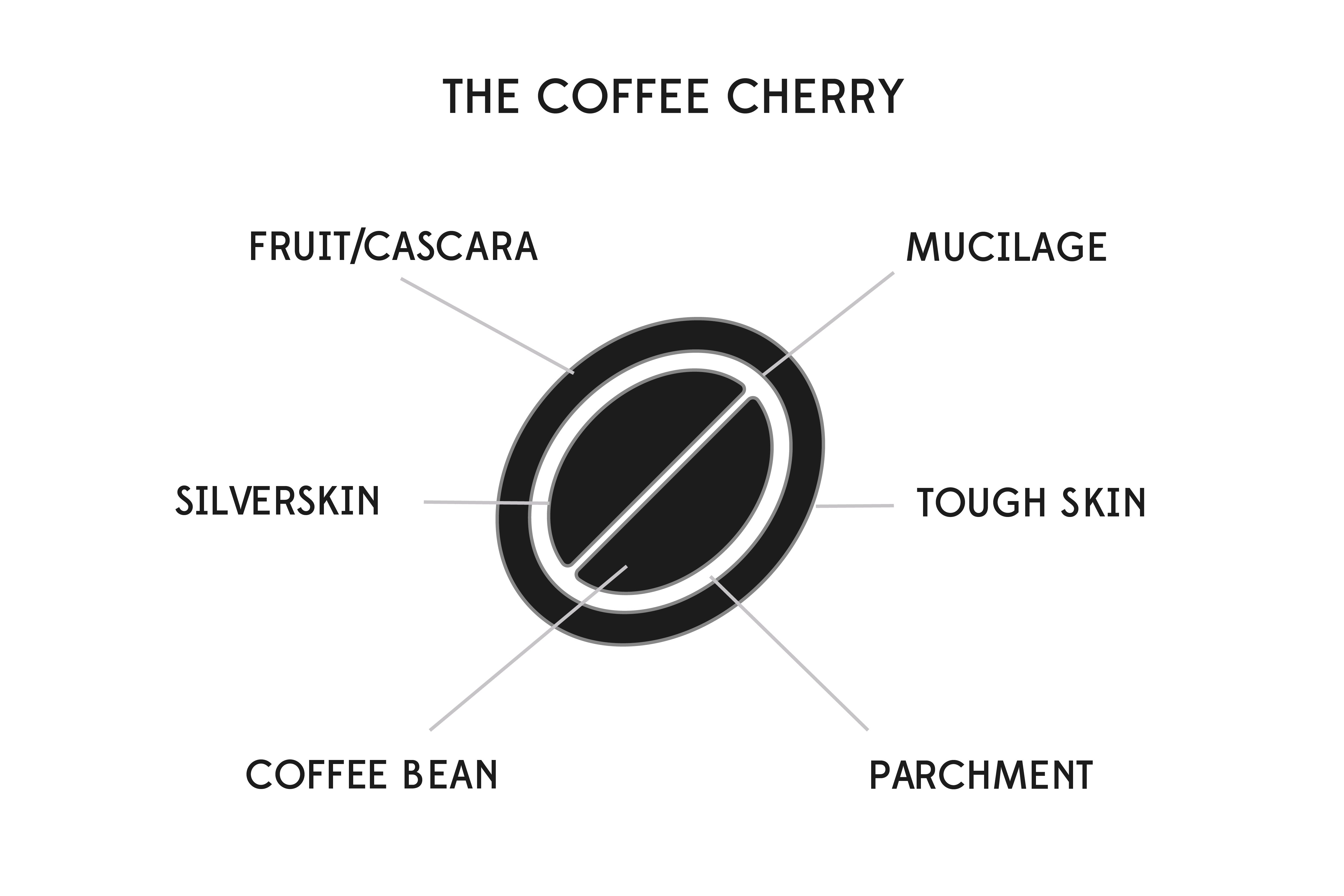

Put simply, coffee processing is the removal of the layers that surround the coffee bean (seed).

A coffee cherry is made up of several layers which include skin, fruit, mucilage and parchment. After the cherries are picked, they require processing which involves removing these layers. This can be done in a number of ways and each process can impart a different cup profile on the coffee. Below are the three most common coffee processes explained in more detail.

WASHED PROCESSING

This method is all about accentuating the inherent flavours of the bean itself.

The washed coffee process involves removing each layer of the coffee cherry before it’s dried. Whilst natural or honey processed coffees utilise the outer fruit to provide some flavour, washed coffees are almost totally reliant on the inner bean having gained enough carbohydrates and flavour during its growth. This means that environmental factors such as climate and terroir, coupled with operational factors such as fermentation and drying, are fundamental in showcasing the coffees true flavour.

To begin, harvested coffee is placed through a de-pulper to remove the skin and fruit. These machines can either be manual, which involve workers turning a wheel-mechanism to de-pulp the coffee, or they can be electric powered. Huge industrialised machines can de-pulp coffee much quicker and more efficiently.

Inside these machines are carefully calculated disks (holes), which drive the coffee beans out of the fruit. As ripe coffee cherries are soft, when they pass through these machines they break and only the coffee seed (bean), passes through successfully. Unripe cherries are separated, often used elsewhere for natural processing, sold for lower prices to local markets or used internally for the workers to drink.

The next stage is to remove the sweet, sticky mucilage that surrounds the coffee bean. This is done by placing the coffee in fermentation tanks for a certain period of time. Although typically between 12-36 hours, producers often experiment with different lengths of fermentation times to affect the profile of the coffee. After fermentation, the coffee is washed with clean water before being dried on patios, tables or raised beds.

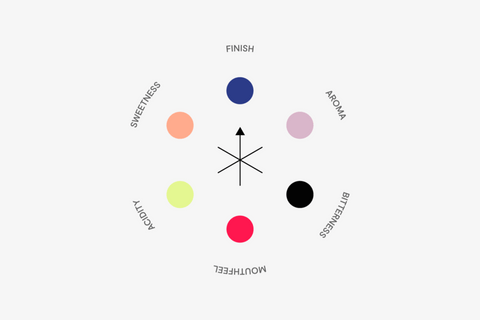

Washed coffees one of the most popular processes. It often gives the coffee a clean, crisp and medium bodied profile.

Shop our current washed coffees

NATURAL PROCESSING

Natural coffee processing is the world’s oldest and riskiest process.

Rather than removing the outer fruit as with washed processing, natural processing involves drying coffee cherries with the fruit and mucilage that surround the bean, left intact. This means that the natural sugars, sweetness and fruit flavours encased in the coffee cherry, begin to ferment and merge with the bean during drying.

Once picked, harvested coffee is sorted using flotation and winnowing techniques before the ripe cherries, in their full form, are taken to a drying area. It’s then placed on surface, usually a patio, table, or raised African bed and left to dry. The next stage must be carefully managed. What makes natural processing so challenging is not only the risk of over fermentation, where the fruit is left to dry for too long, but also of the development of moulds. These moulds at best diminish the coffee flavours and at most cause defective flavours. The coffee is turned frequently to avoid this, ensuring the maximum surface area is exposed to the air to facilitate an even drying. After an agreed amount of time when the coffee reaches a set moisture level, all of the outer layers of the dried cherry are removed in one step by a de-pulper or hulling machine.

This method tends to create a very bright, vibrant and intense cup. Often with high sweetness and heavy body.

Explore our current natural coffees

HONEY/PULPED NATURAL PROCESSING

Honey or pulped natural coffee processing, are terms that are sometimes used interchangeably. The country of origin and producer traditions often dictate whether the coffee is described as a honey or pulped natural.

Broadly speaking, they are a process that sits in between washed and natural. These coffees are often fruit-forward, but with a with medium sweetness and body, showcasing both washed and natural processing cup attributes.

After the harvested coffee is pushed through a de-pulper, rather than placing the coffee in fermentation tanks like with washed processing, the coffee is moved directly to the drying area with the sticky mucilage left intact. Producers often experiment with leaving a different amount on the coffee to achieve different cup profiles and colour. This relates to white, yellow, gold black or red honey coffees which you can learn more about through this by Perfect Daily Grind article.

View our current honey processed coffees

EXPERIMENTAL PROCESSING

There is now more investment into farm level practices than ever before. Producers are investing in new technologies and farming processes, expanding their research capabilities whilst keeping cup quality central to their approach.

To celebrate our fifteen-year anniversary, a few months ago we wrote a journal entry which took a closer look experimental coffee processing. Most notable an award winning ‘Frozen Natural’ process which was developed by our Direct Trade partner, Carlos Pola.